|

Neodymium-Iron-Boron,

General Description

NdFeB Rare Earth Magnets

Rare Earth Magnets are including Neodymium(Nd) -Iron(Fe)-Boron(B) types and Samarium(Sm)- Cobalt(Co) classes. The most commonly produced material is neodymium-iron-boron (NdFeB). This group of magnetic materials provides the highest available magnetic energies of any material. NdFeB magnets allow small shapes and sizes with high magnetic fields. Energy product range from 26 MGOe to about 45 MGOe.

Super-Strength Rare Earth Magnet----Sintered NdFeB magnets, have the characteristics of :

*Extreme strong Br Resident induction.

*Excellent demagnetization resistance capability.

*Good Price relative to its high magnetic properties.

*Coating is needed for NdFeB

Surface Treatment Method: Type Information

Metallic Zinc, Nickel, Nickel+Nickel, Copper+Nickel, Nickel+Copper+Nickel,

Gold, Organic Epoxy, Nickel+Epoxy coating

Temporary Surface: Passivation

Both NdFeB and SmCo are available in sintered as well as bonded forms. Sintered NdFeB parts however, will produce the highest magnetic properties. NdFeB is sensitive to heat and should not be used in the environments that exceed 200 . Bonded NdFeB are generally low in properties due to the special process of gluing the powder in a mold. The bonded form of the material can be produced with close tolerance off tools with little or no finishing required. The sintered form usually some finishing operations in order to hold close mechanical tolerances. . Bonded NdFeB are generally low in properties due to the special process of gluing the powder in a mold. The bonded form of the material can be produced with close tolerance off tools with little or no finishing required. The sintered form usually some finishing operations in order to hold close mechanical tolerances.

Sintered NdFeB Magnet

Neodymium Iron Boron (NdFeB), the most powerful y Rare Earth magnet available today, possesses high energranging from 8MGOe to 48MGOe and wonderful coercive force. As the third generation of Rare Earth permanent magnet, NdFeB products are quite a bit less expensive, and are mechanically stronger and less brittle than SmCo, also density of NdFeB products is about 13% smaller than SmCo products. Because NdFeB magnets are more prone to oxidation than any other magnet alloy, for most applications, coating or plating the magnets is recommended.

Super-Strength Rare Earth Magnet----Sintered NdFeB magnets, have the characteristics of :

*Extreme strong Br Resident induction.

*Excellent demagnetization resistance capability.

*Good Price relative to its high magnetic properties.

*Coating is needed for NdFeB

Surface Treatment Method: Type Information

Metallic Zinc, Nickel, Nickel+Nickel, Copper+Nickel, Nickel+Copper+Nickel,

Gold, Organic Epoxy, Nickel+Epoxy coating

Temporary Surface: Passivation

|

|

|

MAGNETIC AND PHYSICAL CHARACTERISTICS (NdFeB)

|

|

TYPE

|

Remanence

Br

|

Coercivforce

bHc

|

Intrinsic coercive force iHc

|

Max. energy product

(BH) max

|

Working Temperature

|

|

KGs

|

T

|

KOe

|

KA/m

|

KOe

|

KA/m

|

MGOe

|

KJ/m│

|

|

|

1 N-30

|

10.8-11.2

|

1.08-1.12

|

9.8-10.5

|

780-836

|

≥12

|

≥955

|

28-30

|

223-239

|

80 80

|

|

2 N-33

|

11.4-11.7

|

1.14-1.17

|

10.5-11.0

|

836-876

|

≥12

|

≥955

|

31-33

|

247-263

|

80 80

|

|

3 N-35

|

11.7-12.1

|

1.17-1.21

|

10.8-11.5

|

860-915

|

≥12

|

≥955

|

33-35

|

263-279

|

80 80

|

|

4 N-36

|

11.9-12.2

|

1.19-1.22

|

10.8-11.5

|

860-915

|

≥12

|

≥955

|

34-36

|

271-287

|

80 80

|

|

5 N-38

|

12.2-12.6

|

1.22-1.26

|

10.8-11.5

|

860-915

|

≥12

|

≥955

|

36-38

|

287-303

|

80 80

|

|

6 N-40

|

12.6-12.9

|

1.26-1.29

|

10.5-11.0

|

836-876

|

≥12

|

≥955

|

38-40

|

303-318

|

80 80

|

|

7 N-42

|

12.9-13.2

|

1.29-1.32

|

10.5-11.0

|

836-876

|

≥12

|

≥955

|

40-42

|

318-334

|

80 80

|

|

8 N-43

|

13.0-13.3

|

1.30-1.33

|

10.5-11.0

|

836-876

|

≥12

|

≥955

|

41-43

|

326-342

|

80 80

|

|

9 N-45

|

13.3-13.7

|

1.33-1.37

|

10.5-11.0

|

836-876

|

≥12

|

≥965

|

43-45

|

342-358

|

80 80

|

|

10 N-27M

|

10.2-10.6

|

1.02-1.06

|

9.6-10.1

|

764-804

|

≥15

|

≥1194

|

25-27

|

199-215

|

100 100

|

|

11 N-30M

|

10.8-11.2

|

1.08-1.12

|

10.1-10.6

|

804-844

|

≥15

|

≥1194

|

28-30

|

223-239

|

100 100

|

|

12 N-33M

|

11.4-11.7

|

1.14-1.17

|

10.5-11.0

|

844-884

|

≥15

|

≥1194

|

31-33

|

247-263

|

100 100

|

|

13 N-35M

|

11.7-12.1

|

1.17-1.21

|

10.8-11.5

|

860-915

|

≥15

|

≥1114

|

33-35

|

263-279

|

100 100

|

|

14N-36M

|

11.9-12.2

|

1.19-1.22

|

11.1-11.6

|

884-923

|

≥15

|

≥1194

|

34-36

|

271-287

|

100 100

|

|

15 N-38M

|

12.2-12.6

|

1.22-1.26

|

10.8-11.5

|

860-915

|

≥14

|

≥1114

|

36-38

|

287-303

|

100 100

|

|

16 N-40M

|

12.6-12.9

|

1.26-1.29

|

10.8-11.5

|

860-915

|

≥14

|

≥1114

|

38-40

|

303-318

|

100 100

|

|

17 N-42M

|

12.9-13.2

|

1.29-1.32

|

10.8-11.4

|

860-907

|

≥14

|

≥1114

|

40-42

|

318-334

|

100 100

|

|

18 N45M

|

13.3-13.7

|

1.33-1.37

|

10.8-11.4

|

860-907

|

≥17

|

≥1114

|

43-45

|

334-358

|

100 100

|

|

19 N-27H

|

10.2-10.6

|

1.02-1.06

|

9.6-10.1

|

764-804

|

≥17

|

≥1353

|

25-27

|

199-215

|

120 120

|

|

20 N-30H

|

10.8-11.2

|

1.08-1.12

|

10.1-10.6

|

804-844

|

≥17

|

≥1353

|

28-30

|

223-239

|

120 120

|

|

21 N-33H

|

11.4-11.7

|

1.14-1.17

|

10.6-11.1

|

844-884

|

≥17

|

≥1353

|

31-33

|

247-263

|

120 120

|

|

22 N-35H

|

11.7-12.1

|

1.17-1.21

|

10.8-11.5

|

860-915

|

≥17

|

≥1353

|

33-35

|

263-279

|

120 120

|

|

23 N-36H

|

11.9-12.2

|

1.19-1.22

|

11.1-11.6

|

884-923

|

≥17

|

≥1353

|

34-36

|

271-287

|

120 120

|

|

24 N-38H

|

12.2-12.6

|

1.22-1.26

|

11.5-12.0

|

915-955

|

≥17

|

≥1353

|

36-38

|

287-303

|

120 120

|

|

25 N-40H

|

12.6-12.9

|

1.26-1.29

|

11.5-12.0

|

915-955

|

≥17

|

≥1353

|

38-40

|

303-318

|

120 120

|

|

26 N-42H

|

12.9-13.2

|

1.29-1.32

|

11.5-12.0

|

915-955

|

≥17

|

≥1353

|

40-42

|

318-334

|

120 120

|

|

27N-27SH

|

10.2-10.6

|

1.02-1.06

|

9.6-10.1

|

764-804

|

≥20

|

≥1592

|

25-27

|

199-215

|

150 150

|

|

28N-30SH

|

10.8-11.2

|

1.08-1.12

|

10.1-10.6

|

804-844

|

≥20

|

≥1592

|

28-30

|

223-239

|

150 150

|

|

29N-33SH

|

11.4-11.7

|

11.4-11.7

|

10.6-11.1

|

844-884

|

≥20

|

≥1592

|

31-33

|

247-263

|

150 150

|

|

30N-35SH

|

11.7-12.1

|

1.17-1.21

|

10.8-11.5

|

860-915

|

≥20

|

≥1595

|

33-35

|

263-279

|

150 150

|

|

31N-38SH

|

12.1-12.5

|

1.21-1.25

|

10.8-11.5

|

860-915

|

≥20

|

≥1592

|

36-38

|

287-302

|

150 150

|

|

32N-40SH

|

12.6-12.9

|

1.26-1.29

|

10.8-11.5

|

860-915

|

≥20

|

≥1592

|

38-40

|

303-318

|

150 150

|

|

33N25UH

|

9.8-10.2

|

0.98-1.02

|

9.2-9.6

|

732-764

|

≥25

|

≥1990

|

23-25

|

183-199

|

180 180

|

|

34N28UH

|

10.4-10.8

|

1.04-1.08

|

9.8-10.2

|

780-812

|

≥25

|

≥1990

|

26-28

|

207-223

|

180 180

|

|

35N30UH

|

10.8-11.2

|

1.08-1.12

|

10.1-10.6

|

804-844

|

≥25

|

≥1990

|

28-30

|

223-239

|

180 180

|

|

36N35UH

|

11.7-12.1

|

1.17-1.21

|

10.5-11.2

|

836-890

|

≥25

|

≥1989

|

33-35

|

263-278

|

180 180

|

|

37N25EH

|

9.8-10.2

|

0.98-1.02

|

9.2-9.6

|

732-764

|

≥30

|

≥2387

|

23-25

|

183-199

|

200 200

|

|

38N28EH

|

10.4-10.8

|

1.04-1.08

|

9.8-10.2

|

780-812

|

≥30

|

≥2387

|

26-28

|

207-223

|

200 200

|

|

39N30EH

|

10.8-11.2

|

1.08-1.12

|

10.1-10.6

|

804-844

|

≥30

|

≥2387

|

28-30

|

223-239

|

200 200

|

Remark: The above mentioned data of magnetic and physical characteristics are given at room temperature

** The open flux irreversible loss of the testing sample at this temperature 5% 5%

Bonded NdFeB magnets are manufactured by binding rapid-quenching NdFeB powder. The powder is mixed with resin to form a magnet by compression molding with epoxy or infection molding with nylon. The latter technique is particular effective in large volume production, though the magnetic value of products is lower than those made with compression molding because of their relatively lower density. Various shapes of high dimensional accuracy can be produced without further processing. Surface is treated by epoxy coating or nickel-plating to prevent corrosion

Other Properties of NdFeB Bonded Magnets

Hybrid magnets to create different magnetic properties

With different ratio of additives to NdFeB powder, magnetic properties of hybrid NdFeB magnets can be tuned in a wide range. Once the ratio is fixed, magnetic property fluctuation can still be limited in a narrow bank. Hybrid magnets will meet customersí»specified properties.

Characteristics for the initial magnetization of NdFeB bonded magnets

Rapidly quenched NdFeB powder used for bonded magnets is multi grain with grain size of sub-micron. Powder is isotropic in magnetic properties, which results in flat increasing of remanence and intrinsic coercivity with applied field. Magnet can only be magnetized to saturation in high fields.

Advantages of Bonded Magnet

*Produced with high efficiency, stability and repeatability.

*Magnet and other part may form together in one step.

*Free choice of magnetizing direction-especially for multi-polar applications

*High dimensional accuracy-large quantity applications with minimum post-press machining.

*Thin-wall ring and complex shape magnets.

*High resistance to corrosion.

Magnetic properties of bonded NdFeB Magnets

|

P/N

|

Br

Remanence

|

Hcj

Intrinsic Coercivity

|

Hcb

Coercive Force

|

(BH)max.

Maximum Energy Product

|

|

MT

|

kG

|

kA/m

|

kOe

|

kA/m

|

kOe

|

KJ/m3

|

MGOe

|

|

NdFeB-NB6

|

440-560

|

4.40-5.60

|

560-680

|

7.0-8.5

|

240-320

|

3.0-4.0

|

32-48

|

4.0-6.0

|

|

NdFeB-NB8

|

540-640

|

5.40-6.40

|

640-720

|

8.0-9.0

|

320-400

|

4.0-5.0

|

48-64

|

6.0-8.0

|

|

NdFeB-NB8M

|

540-620

|

5.40-6.20

|

1040-1360

|

13.0-17.0

|

384-464

|

4.8-5.8

|

56-72

|

7.0-9.0

|

|

NdFeB-NB10

|

620-700

|

6.20-7.00

|

608-800

|

7.6-10.0

|

360-456

|

4.5-5.7

|

64-80

|

8.0-10.0

|

|

NdFeB-NB12

|

690-760

|

6.90-7.60

|

640-840

|

8.0-10.5

|

400-480

|

5.0-6.0

|

80-96

|

10.0-12.0

|

Physical Chracteristics of bonded NdFeB Magnets

|

P/N

|

Recoil Permeability

|

Hs

Magnetizing Field

|

Ž»

Density

|

Temperature Coefficient

|

Tc

Curie Temperature

|

K[2]

Ring Crushing Strength

|

Coefficient of Thermal Expansion (25-200íŠ)

|

|

|

kA/m

|

g/cm3

|

kOe

|

%/ %/

|

(Hcj)%/ (Hcj)%/

|

|

kg/mm2

|

10-6/

|

|

NdFeB-NB6

|

1.22

|

1600 1600

|

5.1-5.6

|

í╠20

|

-0.14

|

-0.40

|

360

|

5.5 5.5

|

4.8

|

|

NdFeB-NB8

|

1.22

|

1600 1600

|

5.4-5.8

|

í╠20

|

-0.13

|

-0.40

|

360

|

5.5 5.5

|

4.8

|

|

NdFeB-NB8M

|

1.18

|

2000 2000

|

5.8-6.0

|

í╠25

|

-0.12

|

-0.38

|

305

|

5.5 5.5

|

4.8

|

|

NdFeB-NB10

|

1.22

|

1600 1600

|

5.8-6.0

|

í╠20

|

-0.11

|

-0.40

|

360

|

5.5 5.5

|

4.8

|

|

NdFeB-NB12

|

1.17

|

1600 1600

|

5.9-6.1

|

í╠20

|

-0.11

|

-0.41

|

360

|

5.5 5.5

|

4.8

|

Note: [1] The properties given above are typical at room temperature(23 )for uncoated samples. )for uncoated samples.

[2] Ring Crushing Strength K is defined as follows, with the force applying along a diameter of magnet ring and P is the value at which the first crack appears. K=P(D-T)/LT2

K-Ring Crushing Strength(kg/mm2) P-Load on magnet ring(kg)

D-Outer diameter(mm) T-Ring thickness(mm)

L-Height of the ring(mm)

Safety Notes for the Use and Storage of Bonded Magnets.

*Do not place magnets near person wearing electrical medical equipment.such as pacemaker,because the magnet may result in malfunction of the equipment and endanger person's life.

*Keep magnets away from magnetic memory media or other magnetic field sensitive devices such as magnetic cards.tapes,floppy disks,hard disk drivers,and watches.Otherwise information stored in the media or the devices may be damaged.

*Big block of magnet will strongly attract each other or attract iron steel pieces,which may cause serious injure to person.

*Relatively weak in strength,bonded magnets may break into pieces when collide with other materials.Be careful in assembling magnets and prevent the finy fragments from entering into eyes or cause other injuries.

*Keep magnets in good condition and avoid following environment in case that magnets become rust or weaken in mechanical or magnetic strength.

A. With acid,alkali,organic solvent or electrolytes.

B. Immersed in water or in oil.

C. Space filled with hydrogen.

D. Space filled with corrosive gases such as Cl2,NH3,Nox,etc.

E. With radioactive rays.

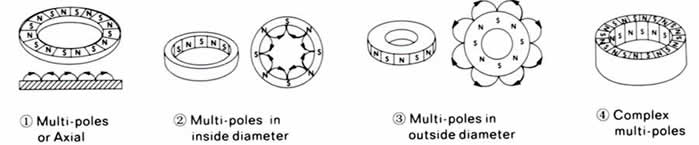

Injection Bonded NdFeB Magnets Injection Plastic NdFeB magnet, a kind of new-generation composite material made from permanent magnetic powder and plastic, has outstanding magnetic properties and plastic properties and features high size precision and exceptional shock resistance. It can be processed into various components with complicated shapes,thus can be used in the industries of micro or special motor, office equipment, instrument, meter, and beeper. Custom design available.

CHARACTERISTICS

1) Design and manufacturing of orientation moulds were carried out

2) Having high dimensional precision and impact-resistance. Capable of forming products with inlay.

3) The injection moulding parts are suitable for forming products with various shapes and thin walls.

4) Multi polar magnetization can be carried out according customer' requirements

APPLICATIONS

*Different kind of micro-special motor

*Different kind of fan motor

*Different kind of DC motor

*Synchronization electric motor

*House electric apparatus

*Ice chipper electric motor

*Hand-operated electric generator

*Automobile motor

*Time gauge

*Instruments for auto

Physical Magnetic properties Of Injection NdFeB Bonded Magnet

|

P/N

|

NBI-4

|

NBI-6

|

NBI-6M

|

NBI-8

|

|

Br (mT)

|

400-490

|

490-570

|

480-560

|

570-630

|

|

bHc(kA/m)

|

256-312

|

312-384

|

336-400

|

382-430

|

|

iHc(kA/m)

|

576-736

|

640-800

|

960-1360

|

680-840

|

|

(BH)max(kJ/m3)

|

28-36

|

40-56

|

44-60

|

60-68

|

|

Recoil permeability

|

1.1-1.22

|

1.1-1.22

|

1.1-1.22

|

1.1-1.22

|

|

Recoil temperature coeffiient of Br. (%/ ) )

|

-0.10

(15-100 ) )

|

-0.09

(15-100 ) )

|

-0.10

(15-100 ) )

|

-0.10

(15-100 ) )

|

|

Magnetizing field (Ka/m)

|

≥ 1592

|

≥1592

|

≥ 1990

|

≥1592

|

|

Density(g/cm3)

|

4.0-4.5

|

4.5-5.5

|

5.0-5.5

|

5.0-5.5

|

|

Ring crushing strength constant (N/mm2)

|

> 78

|

> 78

|

> 78

|

> 78

|

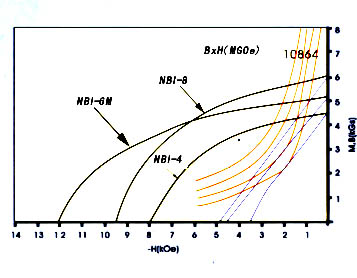

Typical Demagnetization curve of Injection NdFeB Magnet

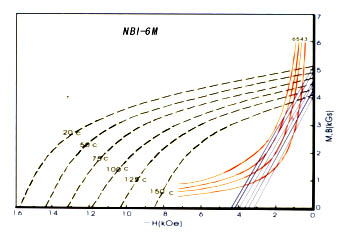

Temperature Characteristic Curve Of Injection NdFeB Magnet

l Inspection standard for permanent magnet

l Purchasing Guide

l Permanent magnet supply direction

l Surface protection and surface coating for the permanent magnet

l Quality warranty

l Safety principle for manual operation of permanent magnet

|