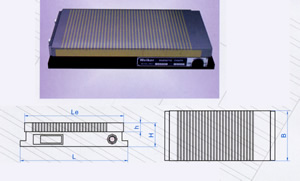

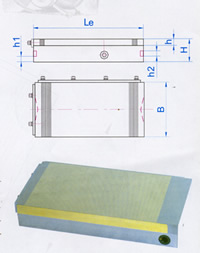

Permanent Magnetic chuckPermanent Magnetic chuck can be used for processing

various magnetic conduction workpieces, especially thin and

small pieces, in-surface grinder, tool grinder and electric

sparks machine tools.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard permanent magnetic chuckFeatures:

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

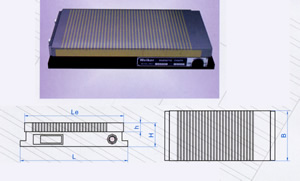

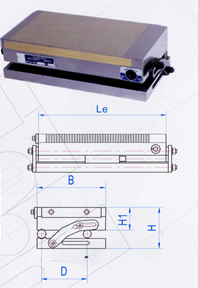

Dense permanent magnetic chuckUsage:

Permanent Magnetic Chuck for fastening thin , small Work piece on Grinding, EDM, especially in liquid. Features: 1) Dense distance between magnetic poles£¬reach (1+0.5)mm and the product can get effective magnetic force. 2) Using special sliding mode ,can control the tolerance accurately. 3) Easy handle operating.

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Distance between magnetic poles (P+P1) reach3mm (1+2)mm

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

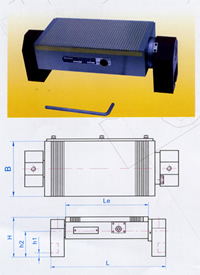

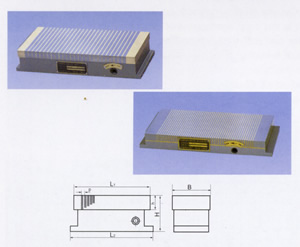

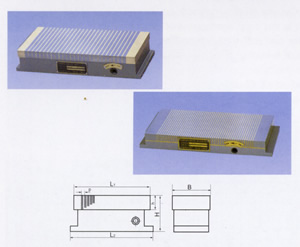

Rotary permanent magnetic chuckUsage: Suited to angle grinding on the grinding machine.

Features: 1)The angle scale on the rotary shaft makes it easy to grind at any angle. 2)High intensity ,the chuck and the shafr as a whole 3)When Turning magnetic force ON/OFF the flat face 's accuracy of magnetic force surface not changed.

|

|

||||||||||||||||||||||||

|

|||||||||||||||||||||||||

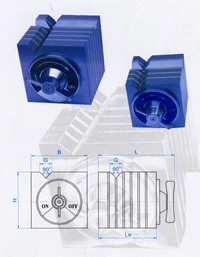

Permanent Square type blockUsage:

Used in surveying ,lineation and light process. Features: 1) no damage to the measured goods .accurately tolerance mensuration. 2) Above ,both sides, V side ,cross side have suction ,could test the difficult special work piece. 3) Simple handle-operated with spiral switch..

|

|

|||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||

|

Permanent magnetic chuck with six face 120N/cm².

Distance between magnetic poles£¬reach1.5mm (1+0.5)mm Usage: Used in in-surface grinder, tool grinder and electric sparks machine tools. Features£ºWhen Turning magnetic force ON/OFF the flat face 's accuracy of magnetic force surface not changed. When processing to the six faces£¬ the accuracy of right angles very high, which could be directly used for well-cut machine tool.

|

|

| Type | B (mm) | Le (mm) | h1 (mm) | h2 (mm) | h (mm) | H (mm) | Weight (Kg) |

| YXS1503 | 150 | 300 | 15 | 15 | 18 | 63 | 18 |

| YXS1535 | 150 | 300 | 15 | 15 | 18 | 63 | 21 |

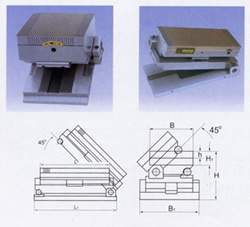

Single sine permanent magnetic chuck- Distance between magnetic poles£¬reach1.5mm (1+0.5)mm Usage£ºUsed in angle grinding in high accuracy Feature£ºWhen Turning magnetic force ON/OFF£¬the flat face 's accuracy of magnetic force surface not changed.¡£The angle could be arbitrarily adjusted at 0-46¡ã according to the different height, processing into the workpiece with different angles. The smaller workpiece is held by the structure of magnet. |

|

| Type | Le(mm) | B(mm) | H(mm) | D(mm) | H1(mm) | Weight(Kg) |

| YXCC1018 | 175 | 100 | 87 | 75 | 47 | 10 |

| YXCC1325 | 250 | 130 | 87 | 100 | 47 | 19 |

| YXCC1515 | 150 | 150 | 90 | 100 | 5305 | 13.5 |

| YXCC1530 | 300 | 150 | 90 | 100 | 50 | 26 |

Technical parameters of ordinary rectangular permanent-magnetic chuck |

|

| Model | B | L1 | L2 | H | h | Polar distance |

| YXPC-1 | 100 | 200 | 220 | 60 | 20 | 10(2+8) |

| YXPC-2 | 100 | 220 | 240 | 60 | 20 | 10(2+8) |

| YXPC-3 | 100 | 260 | 280 | 60 | 20 | 10(2+8) |

| YXPC-4 | 120 | 254 | 274 | 60 | 20 | 10(2+8) |

| YXPC-5 | 125 | 250 | 270 | 60 | 20 | 10(2+8) |

| YXPC-6 | 125 | 300 | 320 | 60 | 20 | 10(2+8) |

| YXPC-7 | 150 | 300 | 320 | 60 | 20 | 10(2+8) |

| YXPC-8 | 150 | 350 | 370 | 60 | 20 | 10(2+8) |

| YXPC-9 | 150 | 400 | 420 | 60 | 20 | 10(2+8) |

| YXPC-10 | 150 | 450 | 470 | 60 | 20 | 10(2+8) |

| YXPC-11 | 150 | 460 | 480 | 60 | 20 | 10(2+8) |

| YXPC-12 | 200 | 400 | 420 | 65 | 20 | 10(2+8) |

| YXPC-13 | 200 | 460 | 480 | 65 | 20 | 10(2+8) |

| YXPC-14 | 200 | 500 | 520 | 65 | 20 | 10(2+8) |

| YXPC-15 | 200 | 560 | 580 | 65 | 20 | 10(2+8) |

| YXPC-16 | 250 | 600 | 620 | 80 | 20 | 10(2+8) |

Technical parameters of fine-pole rectangular permanent-magnetic chuck |

|

| Model | B | L1 | L2 | H | h | Polar distance | Model | B | L1 | L2 | H | h | Polar distance |

| YXF-1 | 100 | 220 | 250 | 40 | 18 | 5(1+4) | YXF-14 | 320 | 1000 | 1030 | 66 | 30 | 5(1+4) |

| YXF-2 | 125 | 250 | 280 | 40 | 18 | 5(1+4) | YXF-15 | 125 | 250 | 280 | 40 | 18 | 1.5(1+4) |

| YXF-3 | 125 | 300 | 330 | 40 | 18 | 5(1+4) | YXF-16 | 125 | 300 | 300 | 40 | 18 | 1.5(1+4) |

| YXF-4 | 125 | 315 | 350 | 40 | 18 | 5(1+4) | YXF-17 | 125 | 315 | 350 | 40 | 18 | 1.5(1+4) |

| YXF-5 | 150 | 300 | 316 | 40 | 18 | 5(1+4) | YXF-18 | 150 | 300 | 316 | 40 | 18 | 1.5(1+4) |

| YXF-6 | 150 | 350 | 380 | 40 | 18 | 5(1+4) | YXF-19 | 150 | 350 | 380 | 40 | 18 | 1.5(1+4) |

| YXF-7 | 150 | 400 | 430 | 40 | 18 | 5(1+4) | YXF-20 | 150 | 400 | 430 | 40 | 18 | 1.5(1+4) |

| YXF-8 | 150 | 450 | 480 | 40 | 18 | 5(1+4) | YXF-21 | 150 | 450 | 480 | 40 | 18 | 1.5(1+4) |

| YXF-9 | 150 | 460 | 490 | 40 | 18 | 5(1+4) | YXF-22 | 200 | 460 | 490 | 40 | 18 | 1.5(1+4) |

| YXF-10 | 200 | 400 | 430 | 50 | 22 | 5(1+4) | YXF-23 | 200 | 400 | 430 | 50 | 22 | 1.5(1+4) |

| YXF-11 | 200 | 460 | 490 | 50 | 22 | 5(1+4) | YXF-24 | 200 | 460 | 490 | 50 | 22 | 1.5(1+4) |

| YXF-12 | 200 | 500 | 530 | 50 | 22 | 5(1+4) | YXF-25 | 200 | 500 | 530 | 50 | 22 | 1.5(1+4) |

| YXF-13 | 200 | 560 | 590 | 50 | 22 | 5(1+4) | YXF-26 | 200 | 560 | 590 | 50 | 22 | 1.5(1+4) |

Technical parameters of single-inclination, double-inclination rectangular permanent-magnetic chuck

|

|

| Model | B | B1 | L | L1 | H | H1 | h | Polar distance | Tilting |

| YXI-1 | 125 | 134 | 315 | 355 | 96 | 40 | 18 | 1.5(0.5+1) | 0-45 |

| YXI-2 | 150 | 150 | 150 | 186 | 92 | 42 | 18 | 5(1+4) | 0-45 |

| YXI-3 | 150 | 150 | 300 | 336 | 92 | 42 | 18 | 5(1+4) | 0-45 |

| YXI-4 | 150 | 150 | 350 | 386 | 92 | 42 | 18 | 5(1+4) | 0-45 |

| YXI-5 | 200 | 200 | 560 | 640 | 124 | 65 | 20 | 10(2+8) | 0-45 |

| YXI-6 | 100 | 140 | 220 | 295 | 146 | 60 | 20 | 10(2+8) | 0-45 |

| YXI-7 | 125 | 165 | 300 | 370 | 155 | 60 | 20 | 10(2+8) | 0-45 |

| YXI-8 | 125 | 174 | 315 | 364 | 138 | 40 | 18 | 1.5(0.5+1) | 0-45 |

| YXI-9 | 150 | 150 | 300 | 336 | 118 | 42 | 18 | 5(1+4) | 0-45 |

| YXI-10 | 150 | 150 | 350 | 386 | 118 | 42 | 18 | 5(1+4) | 0-45 |

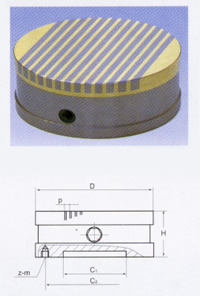

Circular permanent-magnetic chuckThe circular permanent-magnetic chuck can be used as auxiliary tool for various kinds of plain surface grinder, universal tool and lathe for holding ferromagnetic materials for machining. Because it is not require power source, not heated and is with small distortion and high precision, the application scope is very wide. According to its structure, the circular permanent-magnetic chuck can be classified as straight strip fine-pole type, ordinary pole type and radial pole type. |

|

| Model | D | H | C1 | C2 | Z | M | P |

| YX-C1 | 100 | 40 | 60 | 88 | 4 | M6 | 7 |

| YX-C2 | 125 | 62 | 80 | 114 | 4 | M6 | 9 |

| YX-C3 | 150 | 62 | 50 | 130 | 4 | M8 | 9 |

| YX-C4 | 160 | 62 | 100 | 140 | 4 | M8 | 12 |

| YX-C5 | 200 | 67 | 160 | 186 | 3 | M10 | 17 |

| YX-C6 | 250 | 75 | 200 | 224 | 4 | M10 | 14 |

| YX-C7 | 320 | 80 | 265 | 290 | 3 | M12 | 14 |

| YX-C8 | 400 | 92 | 300 | 378 | 6 | M12 | 14 |

| YX-C9 | 150 | 50 | 50 | 130 | 4 | M8 | 5 |

| YX-C10 | 160 | 50 | 100 | 140 | 4 | M8 | 5 |

| YX-C11 | 200 | 64 | 160 | 184 | 3 | M10 | 5 |

| YX-C12 | 250 | 68 | 200 | 224 | 4 | M10 | 5 |

| YX-C13 | 320 | 68 | 265 | 290 | 6 | M12 | 5 |

| YX-C14 | 400 | 68 | 300 | 278 | 6 | M12 | 5 |

| YX-C15 | 200 | 45 | 100 | 186 | 4 | M6 | radial pole |

Permanent Magnetic Super ChuckPermanent Magnetic

Super Chuck is made of high-energy rare earth material (Nd-Fe-B).The

magnetic force is permanent ,which is suitable for the demand

of security and environment protection.There is no risk in the

condition of no electrical source and no distortion brought by

the heat. It will save the fifty percent of the time for clamping

the workpiece when it is used on the machine center. The modular

design enables multiple combinations to meet the requirement of

workpieces of different size.

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Copy Right © 2004-2006 YUXIANG Magnetic Materials Ind. Co., Ltd. All Rights Reserved

Copy Right © 2004-2006 YUXIANG Magnetic Materials Ind. Co., Ltd. All Rights Reserved